2.Key Features of the Software

The software integrates many powerful features to help businesses optimize their production processes:

-

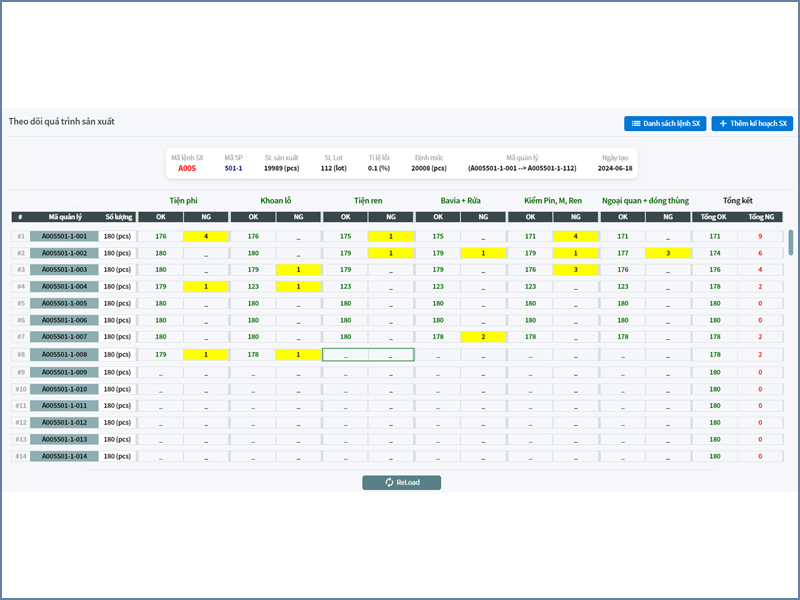

Production planning: Allows businesses to easily plan for each product and allocate tasks efficiently.

-

Product management by lot number: Each product is assigned a unique code, enabling better tracking and control throughout the entire production chain.

-

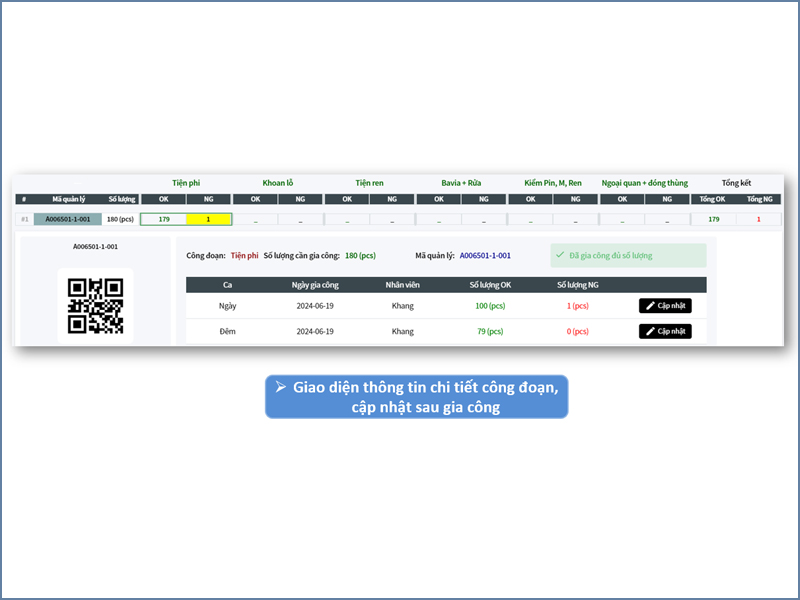

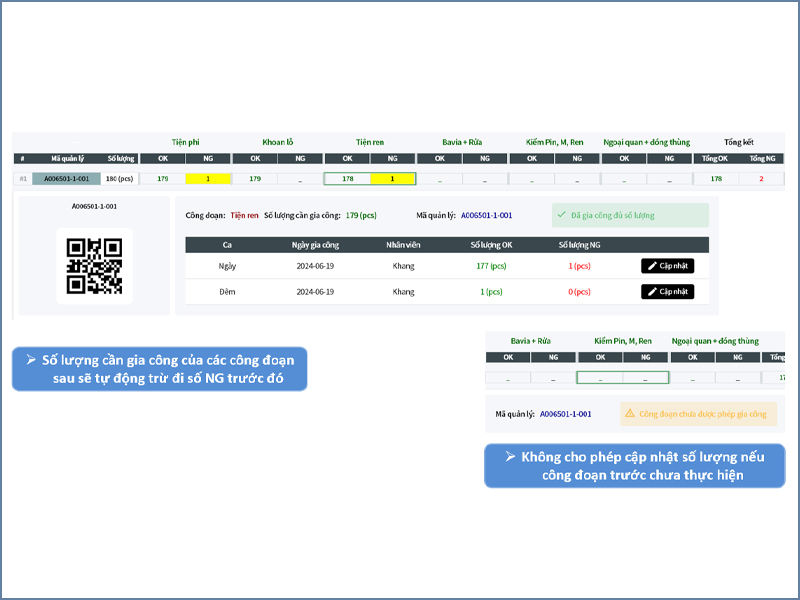

Progress tracking and updates: The system records and reports the quantity of items meeting standards (OK) or not meeting standards (NG) at each stage.

-

Detailed information management: Includes data about employees, machinery, materials, and product codes.

-

Data statistics and retrieval: Provides detailed reports, helping management make accurate decisions based on real-time data.

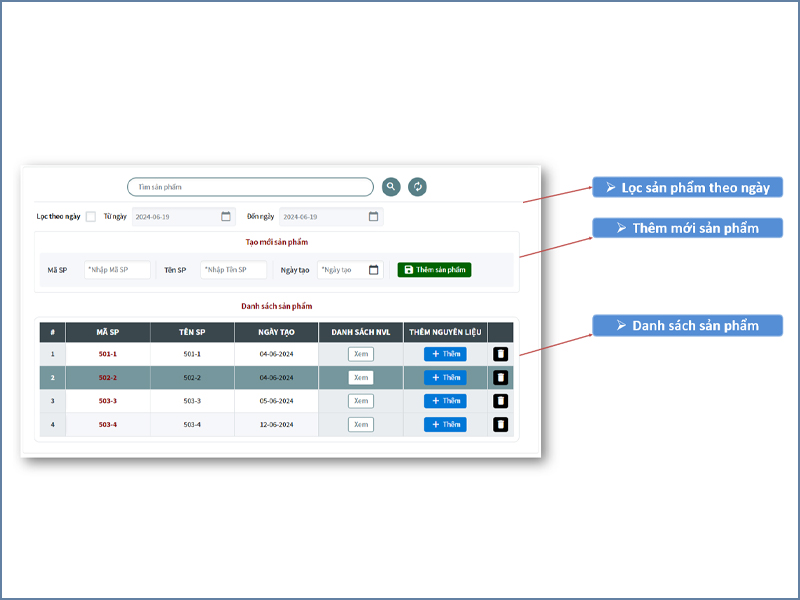

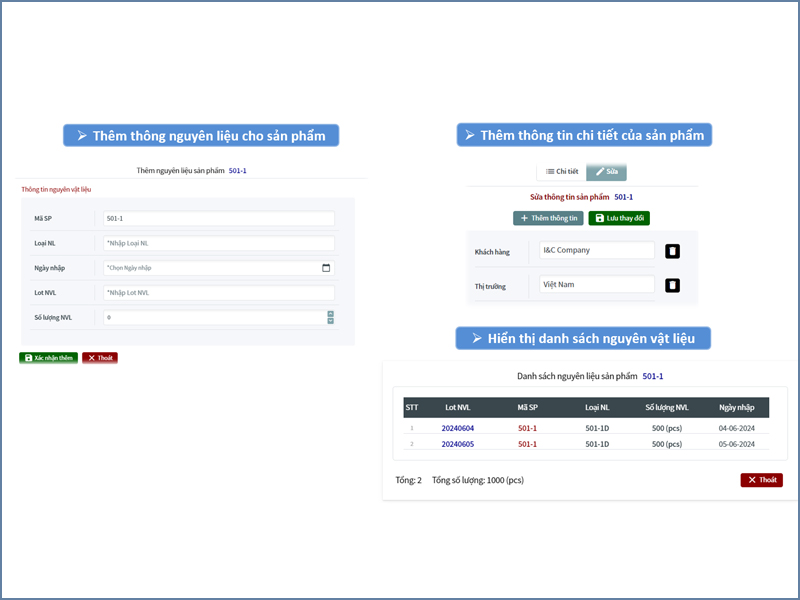

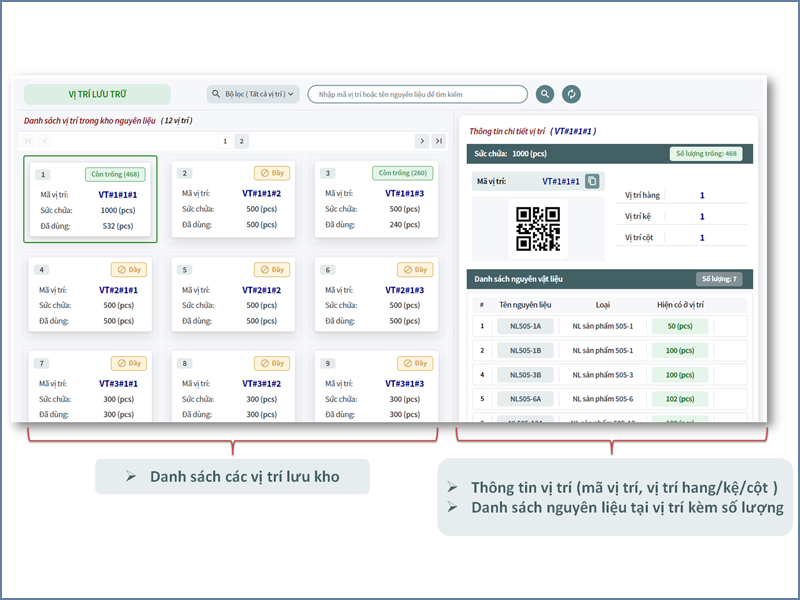

3.Bill of Materials for Products - This feature helps businesses control materials and usage standards:

-

Add new products and materials: Businesses can quickly update the list of products along with the corresponding materials.

-

Material information management: Displays a complete list, helping track the required quantity of materials for each product.

-

Product detailing: Allows for adding specific information about the product, enabling accurate calculation of production standards.